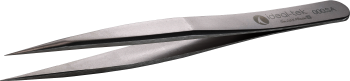

Body material: Stainless steel type SA.

| Item Code |

|

|

|

|

|

|

|

|

|

|

|

|---|---|---|---|---|---|---|---|---|---|---|---|

| 000.SA | STAINLESS STEEL (SA) | 0.17 | 0.20 | 8.00 | 22 | 10 | 0 | 000.SA.0.IT | 1.234.000 đ | ADD |

Price excluding tax

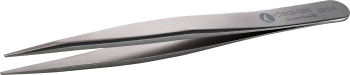

Body material: Stainless Steel type SA.

| Item Code |

|

|

|

|

|

|

|

|

|

|

|

|---|---|---|---|---|---|---|---|---|---|---|---|

| 00.SA | STAINLESS STEEL (SA) | 0.50 | 0.90 | 8.00 | 21 | 10 | 0 | 00.SA.0.IT | 954.000 đ | ADD |

Price excluding tax

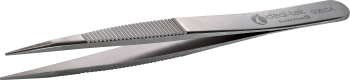

Body material: Stainless steel type SA.

| Item Code |

|

|

|

|

|

|

|

|

|

|

|

|---|---|---|---|---|---|---|---|---|---|---|---|

| 00B.SA | STAINLESS STEEL (SA) | 0.55 | 0.90 | 8.00 | 20 | 10 | 0 | 00B.SA.0.IT | 1.062.000 đ | ADD |

Price excluding tax

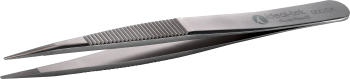

Body material: Stainless steel type SA.

| Item Code |

|

|

|

|

|

|

|

|

|

|

|

|---|---|---|---|---|---|---|---|---|---|---|---|

| 00D.SA | STAINLESS STEEL (SA) | 0.50 | 0.90 | 8.00 | 20 | 10 | 0 | 00D.SA.0.IT | 1.062.000 đ | ADD |

Price excluding tax

Body material: Stainless steel type SA.

| Item Code |

|

|

|

|

|

|

|

|

|

|

|

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0C9.SA | STAINLESS STEEL (SA) | 0.10 | 0.15 | 6.00 | 9 | 10 | 0 | 0C9.SA.0.IT | 968.000 đ | ADD |

Price excluding tax

Body material: Stainless Steel type SA.

| Item Code |

|

|

|

|

|

|

|

|

|

|

|

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.SA | STAINLESS STEEL (SA) | 0.15 | 0.20 | 8.00 | 21 | 10 | 0 | 0.SA.0.IT | 962.000 đ | ADD |

Price excluding tax

Body material: Stainless steel type SA.

Body material: Stainless steel/inox type S.

Body material: Carbon Steel type C.

Body material: Superalloy NC.

Body material: Nonferrous alloy type TA.

| Item Code |

|

|

|

|

|

|

|

|

|

|

|

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1.SA | STAINLESS STEEL (SA) | 0.10 | 0.15 | 0.80 | 14 | 10 | 0 | 1.SA.0.IT | 968.000 đ | ADD | |

| 1.S | INOX (S) | 0.10 | 0.15 | 0.80 | 13 | 10 | 0 | 1.S.0.IT | 1.092.000 đ | ADD | |

| 1.C | CARBON STEEL (C) | 0.10 | 0.15 | 0.80 | 14 | 10 | 0 | 1.C.0.IT | 1.092.000 đ | ADD | |

| 1.NC | SUPERALLOY (NC) | 0.11 | 0.13 | 0.80 | 15 | 10 | 0 | 1.NC.0.IT | 1.794.000 đ | ADD | |

| 1.TA | TITANIUM (TA) | 0.14 | 0.20 | 0.80 | 8 | 10 | 0 | 1.TA.0.IT | 1.456.000 đ | ADD |

Price excluding tax

Body material: Stainless steel type SA.

| Item Code |

|

|

|

|

|

|

|

|

|

|

|

|---|---|---|---|---|---|---|---|---|---|---|---|

| 10G.SA | STAINLESS STEEL (SA) | 0.43 | 0.45 | 8.00 | 14 | 10 | 0 | 10G.SA.0.IT | 1.124.000 đ | ADD |

Price excluding tax

Body material: Stainless steel type SA.

Body material: Superalloy NC.

Body material: Stainless steel type SA.

Body material: Stainless steel/inox type S.

Body material: Carbon Steel type C.

Body material: Superalloy NC.

Body material: Nonferrous alloy type TA.

| Item Code |

|

|

|

|

|

|

|

|

|

|

|

|---|---|---|---|---|---|---|---|---|---|---|---|

| 2A.SA | STAINLESS STEEL (SA) | 0.11 | 1.90 | 8.00 | 15 | 10 | 38 | 2A.SA.0.IT | 954.000 đ | ADD | |

| 2A.S | INOX (S) | 0.10 | 1.60 | 8.00 | 14 | 10 | 0 | 2A.S.0.IT | 954.000 đ | ADD | |

| 2A.C | CARBON STEEL (C) | 0.10 | 1.60 | 8.00 | 14 | 10 | 0 | 2A.C.0.IT | 954.000 đ | ADD | |

| 2A.NC | SUPERALLOY (NC) | 0.11 | 1.90 | 8.00 | 17 | 10 | 0 | 2A.NC.0.IT | 1.778.000 đ | ADD | |

| 2A.TA | TITANIUM (TA) | 0.12 | 1.90 | 8.00 | 9 | 10 | 0 | 2A.TA.0.IT | 1.442.000 đ | ADD |

Price excluding tax